Our Product We Deals With…

Designs For Mild Steel Laser Cutting Offer A Sophisticated Method Of Material Processing In The Built Environment By Fusing Technological Precision With Architectural Beauty In A Seamless Manner. This Cutting-Edge Method Uses A Strong Laser, Usually An O2 Laser, To Precisely Cut Mild Steel Sheets For Precise Architectural Elements. Architectural Applications Need The Development Of Complicated Geometries, Elaborate Patterns, And Highly Detailed Pieces, All Of Which May Be Achieved Through The Precision And Reproducibility Of Laser Cutting. The Laser Beam’s Regulated Energy Reduces Heat-Affected Zones, Producing Crisp Edges And Exceptional Dimensional Precision. Using Mild Steel Laser Cutting, Architects And Designers May Create Bespoke Structural Elements, Ornate Railings, And Beautiful Facades That Combine Aesthetics And Utility. This Creative Mix Not Only Satisfies Structural Specifications But Also Provides A Degree Of Fine Detailing That Gives Architectural Ideas A Distinct Visual Depth. Mild Steel Laser Cutting Keeps Expanding The Boundaries Of Technical Accuracy In The Field Of Architectural Aesthetics As Technology Develops.

Mild Steel Laser Cutting

Stainless Steel Laser Cutting Designs Provide An Elegant Method Of Metal Manufacture Inside The Framework Of The Built Environment By Skillfully Fusing Technical Accuracy With Creative Architectural Design. This Procedure Allows Architects To Accurately Cut Through Stainless Steel Sheets, Achieving Clean And Sharp Edges Necessary For Architectural Detailing. It Does This By Utilizing Advanced Laser Technology, Specifically Fiber Lasers. Stainless Steel Is A Great Material For Structural As Well As Decorative Purposes Because Of Its Strength And Resistance To Corrosion. Intricate Patterns, Unique Geometric Shapes, And Personalized Designs That Adhere To Exacting Technical Requirements Can Be Produced With Laser Cutting, All While Enhancing The Visual Language Of Architectural Features. Stainless Steel Laser Cutting Designs Represent The Union Of Cutting Edge Technology And Architectural Aesthetics, Enhancing The Built Landscape With Useful And Aesthetically Pleasing Features. Examples Of These Designs Range From Elaborate Railings And Façade Embellishments To Modern Sculptures.

Stainless Steel Laser Cutting

Designs For Laser Cutting Brass Sheets Combine Technical Accuracy And Creative Architectural Design To Create A Special Kind Of Metal Fabrication That Is Specifically Suited For The Built Environment. Using State-Of-The-Art Laser Technology—Mostly Fiber Lasers—This Procedure Makes It Possible To Precisely And Painstakingly Cut Brass Sheets. Architects Use Brass’s Many Qualities—Such As Its Timeless Beauty And Durability—To Create Unique, Complex Designs For A Variety Of Architectural Purposes. These Brass Elements Can Be Easily Incorporated Into Structural Components, Ornamental Facades, And Custom Interior Accents Thanks To The Precision Of Laser Cutting, Which Guarantees Clean Edges And Polished Details. Because Brass Is Reflective, It Adds A Play Of Light And Shadow To Architectural Spaces, Enhancing The Visual Experience. Designs For Brass Sheet Laser Cutting Represent The Fusion Of Technological Know-How And Creative Architectural Design, Resulting In Environments That Satisfy Structural Needs While Also Adding A Touch Of Refinement And Long-Lasting Aesthetic Appeal.

Brass Laser Cutting

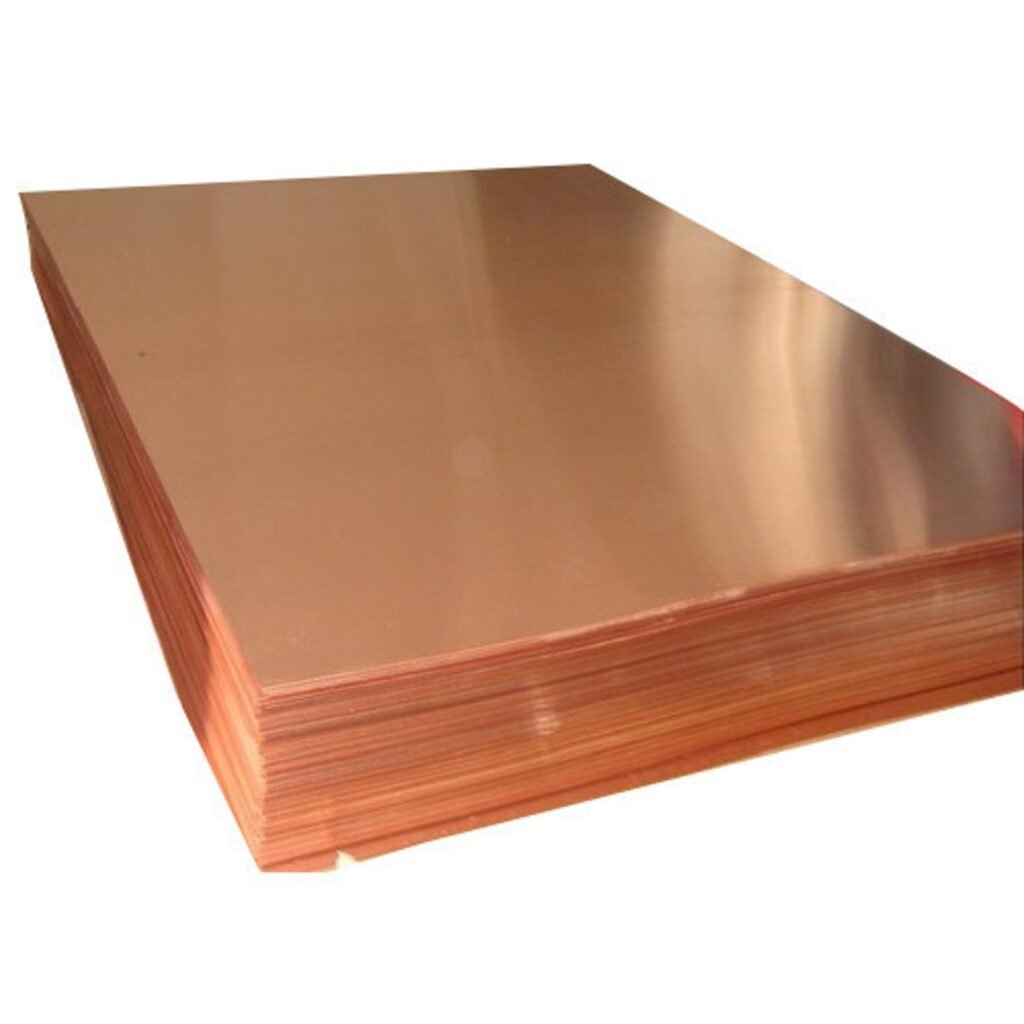

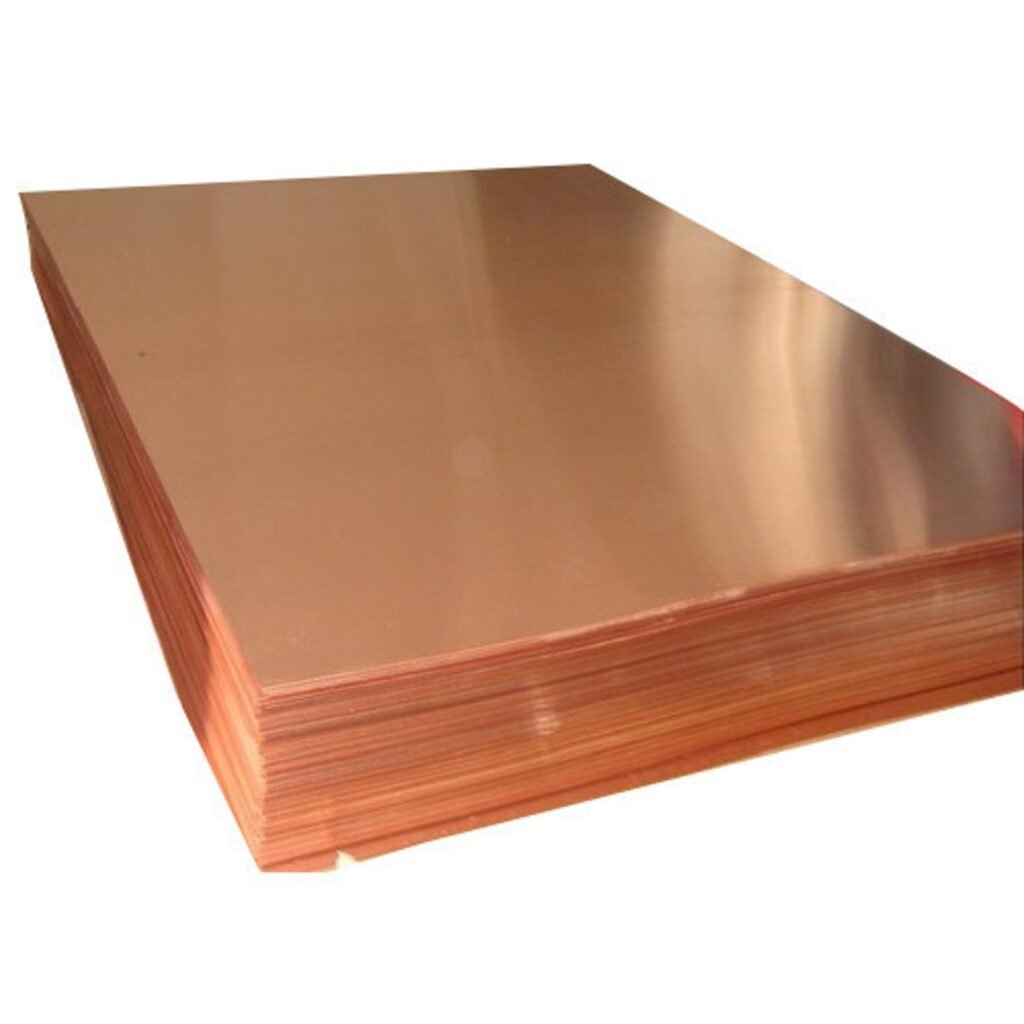

Designs For Copper Sheet Laser Cutting Combine Architectural Originality And Technical Perfection In A Seamless Manner, Exemplifying The Perfect Marriage Of Cutting-Edge Production Technology With Creative Expression. By Employing State-Of-The-Art Laser Technology, Specifically Fiber Lasers, This Procedure Makes It Possible To Precisely And Painstakingly Shape Copper Sheets. Using Copper’s Unique Properties—Such As Its Thermal Conductivity And Eye-Catching Appearance—Architects Create Unique Designs For Use In Architecture. Architectural Features Such As Facades, Decorative Panels, And Custom Interior Accents Can More Easily Include These Copper Pieces Because Laser Cutting Guarantees Precise Edges And Detailed Details. Laser Cutting’s Built-In Temperature Management Complements Copper’s Conductivity, Making For A Precise And Regulated Procedure. Thus, Copper Sheet Laser Cutting Designs Go Beyond The Merely Technical, Helping To Create Architectural Spaces That Radiate Artistic Sophistication While Meeting Structural Requirements. In These Spaces, The Play Of Light And Shadow On Copper Surfaces Becomes An Essential Component Of The Overall Spatial Experience.

Copper Laser Cutting

Acrylic sheet router cutting ideas provide a flexible way to shape acrylic materials in the built environment by fusing technical accuracy with creative architectural design. With the use of high-speed rotating tools and router cutting technologies, architects may accurately produce geometric shapes, complicated patterns, and personalized elements out of acrylic sheets. This technique is used in architectural features like decorative panels, signage, and transparent partitions because it guarantees smooth edges and a polished finish. Acrylic’s transparency increases its versatility, which makes it a desirable material for architectural parts that need to be both aesthetically pleasing and useful. In addition to satisfying structural requirements, router cutting’s technological acumen allows architects to incorporate creative detailing into their plans, enhancing spaces with one-of-a-kind and spectacular acrylic installations. Thus, acrylic sheet router cutting designs provide a sophisticated solution for a variety of design applications, bridging the gap between technological innovation and architectural expression.